Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

When it comes to the various construction materials, the PVC pipe is quite popular. This is probably due its durability and its low cost. PVC pipe has a wide range of applicability. They are used in most drainage systems, as conduit for underground water supply and in ventilation systems. There is a general believe by most homeowners that PVC is maintenance-free and however pay less attention to the material. To a large extent, the strength of the PVC will depend on its manufacturing process as well as its application.

However, when PVC pipe is placed in a few scenarios for a long period of time, it can become brittle and crack. Apart from the condition mentioned, the manufacturing process has a lot of roles to play on the integrity of the PVC plastics. This is why PVC profile machine manufacturers need to take proper precautions during the production process.

Here, we will be looking at some of the factors that contributes to the brittleness of the PVC plastic profiles and the possible solutions.

Ultraviolet light also known as UV light from the sun has been found to break down white PVC pipes which are commonly used in plumbing activities. Excessive exposure to the sun weakens the material. This explains why it is unsuitable for outdoor applications where the entire length will be left uncovered. Such activities include rooftop applications, flag poles and more. The rays from the sun degrades the polymer and reduces the flexibility leading to splitting, cracking and splintering.

Low temperatures and prolonged cold conditions or freezing temperatures increase PVC brittleness. This could also lead to crack. To avoid this, do not PVC to extreme or prolonged cold conditions. Also, do not allow water to freeze inside the PVC pipe to avoid bursting or splitting.

Just like every other material, PVC undergo some level of degradation over a period of time. Important components such as plasticizers which are added to PVC during the manufacturing to increase their flexibility are leeched over time. This will lead to cracking or splitting of the material.

Polymers react to certain chemicals which loosen the molecular bonds in the plastic. This could make them brittle depending on the amount and concentration of the chemical substance plus the period of exposure. Proper application of the PVC plastic is necessary to avoid such chemical degradation.

Today, PVC pipes are applied in a wide range of projects from sink drains to duct work. One typical example is the PVC marble plastic. PVC Marble Profile are mainly applied on elevator door frame, skirting board, door frame, window frame, background wall, wall panel, ceiling and more. During the PVC marble profile production, care has to be taken to ensure that they are scratch resistant as well as wear resistance. This is one of the ways to ensure that they become durable.

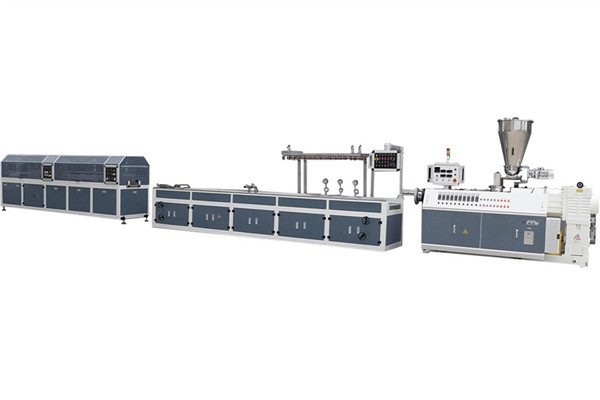

However, the type and model of the PVC profile line and equipment contributes to the quality of the PVC plastic product. This is why it is important to liaise with reputable and PVC profile line manufacturers to get a top quality equipment for your production needs.