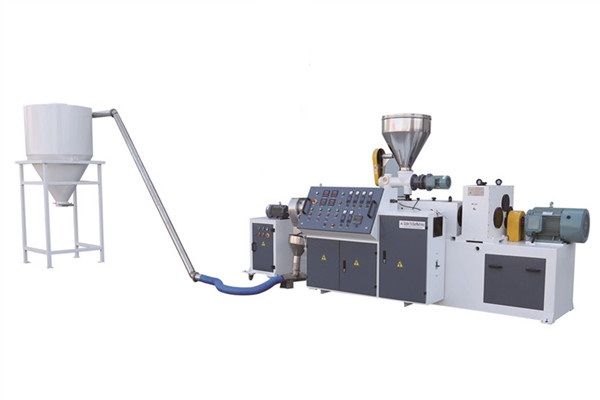

Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

Irrespective of a plastic granulating line cost, the blade which is usually found within the cutting chamber seems to be one of the most important parts or components of a granulator.

However, one common challenge in which many PVC granulators manufacturer are still yet to give a final and lasting solution is having the cutting edge of a granulating machine go blunt.

And once the blade or knife of a granulator goes dull, it then means that the machine will use a higher level of energy to achieve the cutting of materials.

Besides the machine requiring more energy to cut materials as a result of a failed blade, a dull granulator blade usually leads to an increased level of dust and fines during the grinding of plastic materials.

Consequently, the implication of an increase in the level of dust from a failed blade also involves a poor regrind quality, which in most cases will lead to the production of particles of different sizes.

Looking at the high level of importance of the PVC granulator blade to your overall production quality, it is highly recommended that you sought for a high-quality PVC granulator from a professional and experienced PVC granulator manufacturer.

With this, you are sure of investing in the right granulating line with a cutting blade of the highest quality that can stand the test of time.

Balancing Toughness and Wear Resistance When Choosing Granulator Blade

Choosing an improper blade for your PVC granulator seems to be one of the major causes of premature blade failure.

Generally, D2 steel which is hardened to about 59HRC Rockwell remains the most commonly used type of blade that is employed in the manufacture of granulator knives, and they are perfect for various cutting applications.

Well, one thing you must always remember is the fact that each granulator operates in a unique manner, and so you must evaluate your blade hardness in order to have the best blade life and output.

As the first step in optimizing your granulator blade, you must choose a blade with the right balance of both hardness as well as wear resistance.

This is important because as a steel material used in the manufacture of granulator blade is hardened, the more it losses its toughness, and gains wear resistance. In order words, this means that the blade will be more brittle and can last for a longer time, especially when used for the right application.

Factors To Consider When Choosing PVC Granulator Blade

1. Get A Customized Granulator Blade For Your Use

One major challenge a lot of users undergo is finding out that their granulator blade is either too hard or too soft for their intended use, and this is a common cause of blade edge failure.

However, with the help of an experienced blade manufacturer, you can have a customized hardness for your granulator machine. For instance, a blade made of D2 steel is easier to be hardened to about 56-59 Rockwell, especially when the blade material doesn’t contain too much tramp material.

2. Evaluate The Base Material Of Your Granulator Blade

Although D2 steel remains the most commonly used material for the manufacture of the granulator blade, some other granulating needs may require a non-D2 steel material.

For instance, modified A8 steel, which is the best steel material used in the manufacture of wood chipping blade can serve as the best blade material for cutting dense material since it has a higher level of toughness at a hardness level of 56-58HRC compared to D2 steel

Bottom Line

For the best PVC granulating experience, using an optimum granulator blade material is key. This is usually a function of a balance between both the wear resistance and the toughness of the steel material used.

For the best working experience using the PVC granulating machine, it is expedient to work with a professional PVC granulator manufacturer for the best granulating machine as well as a well-customized blade that will match your unique application.