Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

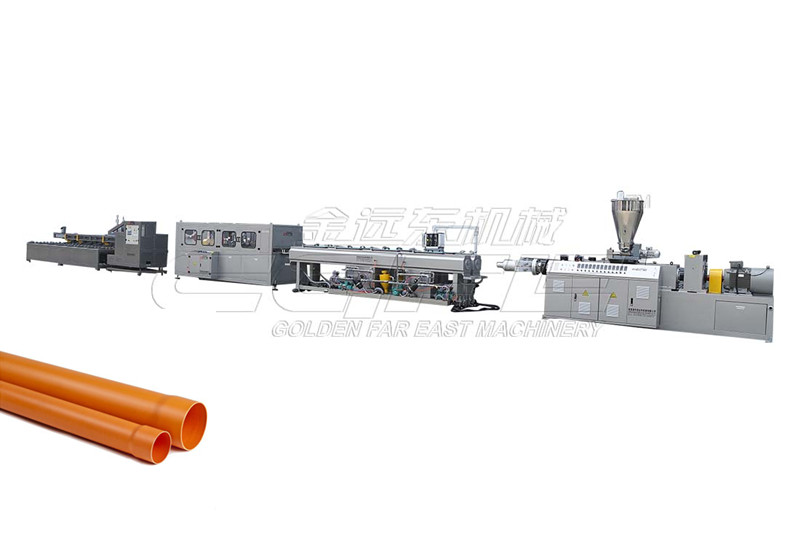

A plastic pipe extrusion line is a manufacturing process used to produce plastic pipes of various sizes and shapes. It involves the extrusion of molten plastic material through a die, which gives the pipe its desired shape. Here are some key points about plastic pipe extrusion lines:

The process begins with the feeding of plastic material, typically in the form of pellets, into an extruder. The extruder melts the plastic and forces it through a die, which determines the size and shape of the pipe. The extruded pipe is then cooled and cut to the desired length.

Plastic pipes can be made from various types of thermoplastic materials, such as PVC (Polyvinyl Chloride), PE (Polyethylene), PP (Polypropylene), and ABS (Acrylonitrile Butadiene Styrene). The choice of material depends on the intended application and required properties of the pipe.

Plastic pipe extrusion lines can produce pipes of different diameters and lengths, ranging from small tubes to large-diameter pipes used in construction and infrastructure projects. The shape of the pipe can also be customized, including round, square, rectangular, or other profiles.

Plastic pipes find applications in various industries, including plumbing, irrigation, drainage, gas distribution, telecommunications, and more. They are known for their durability, corrosion resistance, and ease of installation.

Plastic pipe extrusion offers several advantages over traditional pipe manufacturing methods. It allows for continuous production, high production speeds, and precise control over pipe dimensions. The process is also cost-effective and can produce pipes with consistent quality.

Plastic pipe extrusion lines play a crucial role in the production of plastic pipes, providing a reliable and efficient method for meeting the demand for pipes in various industries.