Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

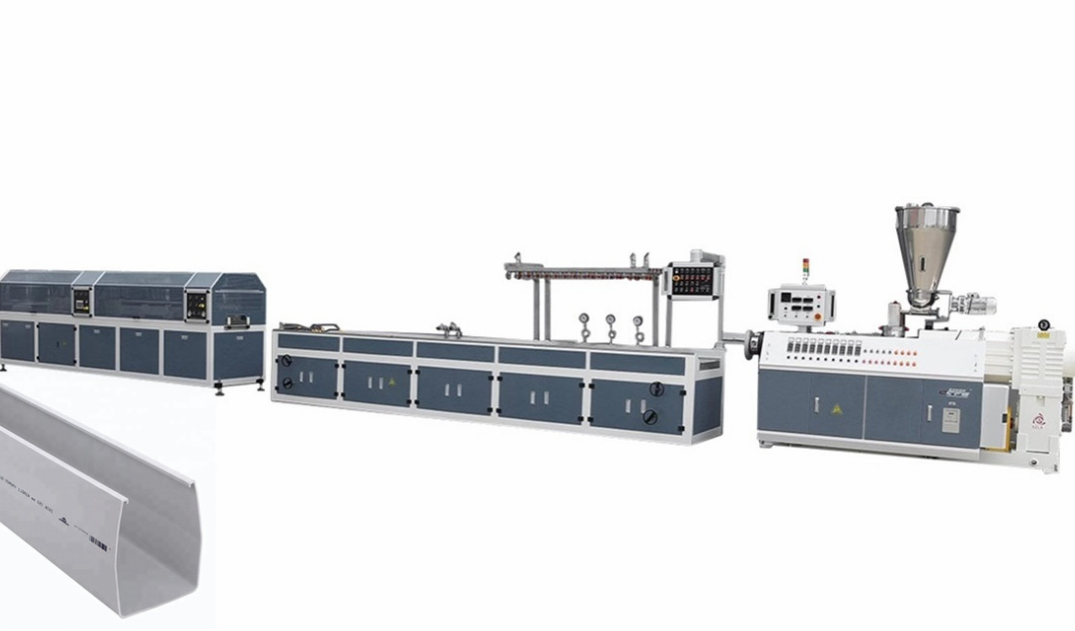

Profile extrusion is extrusion of a shaped product that can be a variety of configurations but does not include sheet or film products. Profile extrusion can include solid forms as well as hollow forms. Products ranging from tubing to window frames to vehicle door seals are manufactured this way and considered profile extrusion.

To process hollow shapes a pin or mandrel is utilized inside the die to form the hollow sections. Multiple hollow sections require multiple pins. To create these hollows a source of air is required to allow the center of the product to maintain shape and not collapse in a vacuum. Usually an air source will be utilized to keep the correct airflow in the cavity.

If two or more materials are required to make a product, the co-extrusion process is used. For example, a white drinking straw that has 2 colors of stripes on it, requires a total of 3 extruders. Each extruder feeds a different material or variation of the same material into a central co-extrusion die.

A wide variety of materials are used in the extrusion process. Here we can take the example of the PVC extrusion process. Some other materials are polyethylene, acetal, nylon, acrylic, polypropylene, polystyrene, polycarbonate, and acrylonitrile. These are the primary materials used in the extrusion process. However, the process is not limited to these materials.

To understand the plastic extrusion process, it is useful to get a picture of what an extruder is and how it works. Typically, an extruder contains the following parts:

ü A hopper, where the raw plastic is kept

ü A feedthroat, where the plastic enters the barrel from the hopper

ü A heated barrel, containing a screw driven by a screw drive motor that forces material to the feedpipe

ü A breaker plate, fitted with screens to filter the material and maintain pressure

ü A feedpipe, where the now molten material exits the barrel and is delivered to the die

ü A die, which shapes the material into the desired extrusion profile

ü A separate cooling system, which helps the extrusion solidify evenly

Profile extrusion is feasible for companies of all sizes, and includes several benefits:

Reduced costs, increased efficiency. The ability to extrude a large portion of plastic products can make the production process more efficient and cost effective, while still providing customers with the same quality products.

Environmentally-friendly. Plastics Design & Manufacturing has taken every opportunity to utilize sustainable methods that help prevent unnecessary waste of resources. Typically, plastics companies discard large amounts of leftover materials.

Golden Far East Machinery Co., ltd. is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines.

Our products include single screw extruder, twin screw extruder, PVC/HDPE/PP-R pipe extrusion line, PVC profile extrusion line, WPC profile extruding line, high speed mixer and plastic sheet production lines with the relative plastic auxiliary machine, etc. If you have any need for above mentioned machines, please kindly contact us.