Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

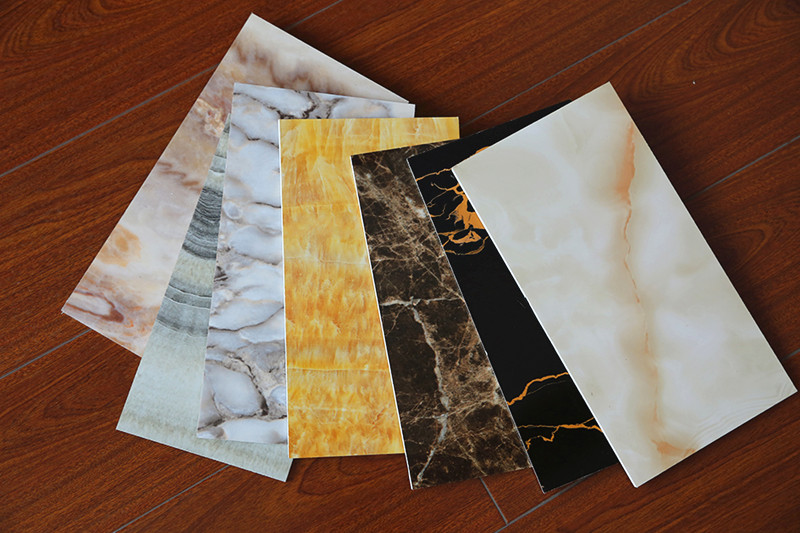

PVC imitation marble decorative board is a kind of decorative product with lifelike texture, pattern and texture of natural marble. It not only has lifelike decorative effect of natural marble and superior performance of ceramic tiles, but also abandons various natural defects of natural marble. It is an epoch-making innovator in the decoration industry and also a representative work of modern top wall decoration. It is following ceramic chips, polished bricks Another new category of wall board after antique brick and microcrystalline stone ceramic tile. High grade home decoration should use wall board, and the first choice should be imitation marble decorative board.

PVC is a common plastic raw material and one of the largest plastic products in the world. It is cheap and widely used. Different additives can be added according to different uses. PVC can show different physical and mechanical properties. A variety of hard, soft and transparent products can be made by adding an appropriate amount of plasticizer.

UPVC has good tensile, flexural, compressive and impact resistance, and can be used as structural materials alone. The softness, elongation at break and cold resistance of soft PVC will increase, but the brittleness, hardness and tensile strength will decrease. Among them, hard PVC accounts for about 2 / 3 of the market and soft PVC accounts for 1 / 3. Soft PVC is generally used for floor, ceiling and leather surface. PVC hard board is widely used in the chemical industry to make the lining of various storage tanks, corrugated boards of buildings, door and window structures, wall decorations and other building materials.

So what are the properties of PVC imitation marble decorative board with realistic texture, pattern and texture of natural marble:

1. The material composition is polymer material, 100% waterproof, so there are no problems such as mildew and moisture.

2. The surface is high-definition, three-dimensional effect is strong, and the simulation degree is more than 95%.

3. After UV special treatment on the surface, the board surface is flat, not easy to scratch and convenient for dust removal.

4. All colors are made of imported jade grain scanning synthesis, which gives people a luxurious, fashionable and high-grade atmospheric style as a whole!

5. Acid and alkali resistance and corrosion resistance. Compared with traditional plates, it has better physical and chemical properties, ensures that EO plates will not lose color for a long time, and solves the phenomenon of color difference

6. Replace the disadvantages of traditional UV board, crystal plate, aluminum-plastic board, cement fiber board, stone grain board, etc., such as unclear surface, poor three-dimensional effect and high cost

7. Instead of artificial jade, artificial stone, marble ceramic tile, wood decorative panel and other wall materials, it has the disadvantages of high cost, inconvenient installation, troublesome cutting and so on.

WOW! What is the production process of such a super high-performance decorative board?

⑴ PVC, calcium carbonate and other raw materials → feeding → hopper storage → extruder feeding → extrusion molding (online pasting imitation marble film and protective film) → traction → cutting → inspection → warehousing

(2) calcium carbonate and other raw materials → feeding → hopper storage → extruder feeding → extrusion molding → traction → cutting → inspection → UV curing treatment → protective film treatment → inspection → warehousing

The following small series will give you a detailed introduction to the advantages of PVC imitation marble decorative board to further uncover its mystery

1. PVC decorative board has heat insulation, heat preservation, moisture-proof, flame retardant, acid and alkali resistance and corrosion resistance.

2, stability, good dielectric properties, durability, aging resistance, easy melting and bonding.

3. The bending strength and impact toughness are strong, and the elongation is high during fracture.

4. The surface is smooth, bright color, highly decorative, and has a wide range of decorative applications.

5. Decorative materials have stable quality, pure color and rich embossing.

6. The construction process is simple and the installation is convenient.

We introduced the performance and advantages of such PVC imitation marble decorative board. Let's pick up the points that should be paid attention to in the installation of his products!

1. Internal wall use: if there is a layer of cement mortar on the rough embryo wall, it is flat and the sand does not fall off, it can be pasted directly to the rough embryo wall. The glue used is 955 silicone structural glue; If the wall is not flat, a layer of blockboard with a thickness of more than 5% shall be applied, and then pasted.

2. Use of background wall: after the wood board completes the modeling frame, paste it directly on the wood board. Structural adhesive, nail free adhesive and universal adhesive can be used.

3. The product is cut with woodworking saw, which can be nailed, planed, drilled and polished.

Where can PVC imitation marble decorative board be used in home decoration?

Interior wall decoration engineering places such as home decoration background wall, wall, dado, hotel, KTV, hotel, shopping mall and entertainment places. Replace artificial stone, marble tile, wood veneer and other wall materials.