Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

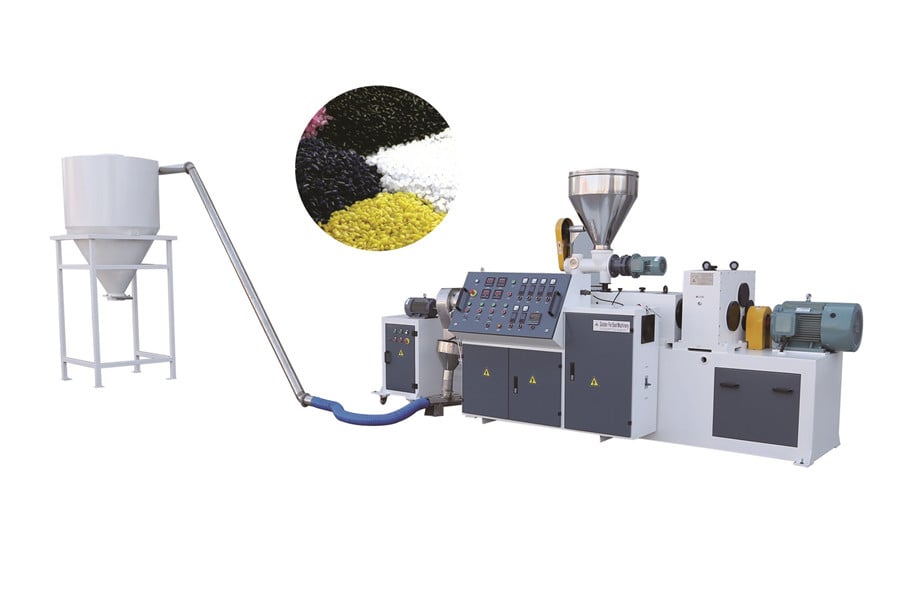

The PVC granulating equipment is made up of a conical dual screw extruder along with granulating equipment, and it is suited for granulating PVC, and PE raw materials using wood power, or even other additives.

PVC granulating machines generate even, solid, and attractive pellets.

The pelletizing downstream equipment consists of a hydraulic net changer, a die face cutter, vibration separating, an air transferring unit, and other components.

PVC granulating machine has excellent plasticizing, high level of production efficiency, impact construction across the line, and high automation.

PVC powder can be used with other materials like CaCO3, CPE, Static, and wax. The granules could be used to make PVC profiles, shoes, and other items.

So, whenever you require a PVC granulating line, make sure it comes from a reputable manufacturer.

The simple fact that PVC is frequently used in the manufacture of many different products demonstrates how its inherent properties are incredibly valuable and unique.

Let's start with PVC rigidity: the material is highly stiff when pure, but it gets flexible when mixed with other chemicals.

This distinguishing feature makes PVC excellent for the production of products utilized in a variety of industries, ranging from construction to automotive.

However, not every property of the material is useful. PVC's melting temperature is rather low, making it unsuitable for locations where very high temperatures can be reached.

Furthermore, risks might arise from the fact that when PVC overheats, it releases chlorine molecules in the form of dioxin or hydrochloric acid.

Contact with this material could result in irreversible health problems.

To make it more suitable for industrial production, PVC is mixed with stabilizers, plasticizers, colorants, and lubricants.

This mixture aid in the manufacturing process and make PVC more malleable and resistant to wear and tear.

keep in mind the following factors while operating a PVC granulating production line.

1. Avoid running the granulator in reverse.

2. Pay close attention to the machine's operation; for example, if the speed is slow or the operating temperature is high, these issues can be addressed as needed.

3. Whenever the speed reducer burns out or makes noise, it should be handled in time.

4. The granulator ought to prevent cooling machine activity; the operation needs to be filled to avoid the hugging (patch) issue.

5. Avoid production-impacting incidents.

6. Whenever the bearing section of the host bearing chamber produces noise or has hot burns, the process has to be stopped. The bearing room is more than 5-6 days while working well.

7. Once the fuselage is unsteady, it is important to recognize that the distance within the coaxial anastomosis is overly tight and must be relaxed over time.

Our services include uniform direction of parallel twin screw equipment, hot-cooled mold surface, pull strip granulation, refining extrusion production line.

We also provide customers with plastic intelligent production environment integral solutions.

So, please contact us if you are interested in purchasing PVC granulating line that meets all safety regulations.