Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

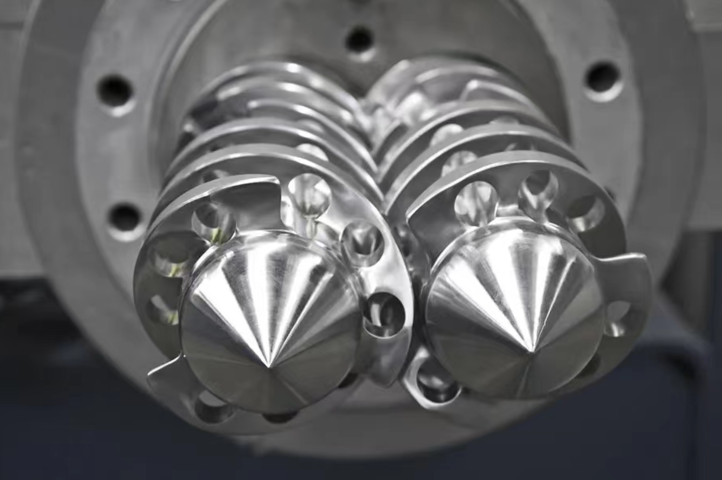

Screw-extruder is the core equipment in plastic forming and blending modification. In the actual process of blending modification, the screw of the extruder is in a harsh environment with high pressure and high temperature and is subjected to tremendous friction and shear forces.

Due to the special working environment, the screw friction is not the common metal-to-metal, but rather metal-to-high-molecular polymer, so the screw surface often gets heavily worn. The abrasion of the screw increases the distance between it and the barrel, which affects the compression and shear of the screw on the material, leading to a decrease in product quality. On the other hand, frequent replacement of worn-out screws increases costs and delays production schedules, resulting in lower productivity.

Screws have to be scrapped is generally due to that the clearance between screw and barrel is so large after a long-term abrasion that the material can’t be normally extruded, and also there’re examples that the machine's working ability goes beyond the limit because of improper design or operation. The following is a brief description of the causes of screw abrasion.

Each plastic has a processing temperature range for ideal plasticization, and the barrel processing temperature should be controlled so that it is close to this temperature range. Plastic pellets are conveyed from the hopper to the barrel, and they will first reach the filling section. In the filling section, materials will inevitably have dry friction. When these plastics are underheated, and unevenly melted, it is easy to increase abrasion between the inner wall of the barrel and the screw surface.

Similarly, in the compression section and homogenization section, if the molten condition of the plastic is disordered and uneven, it will also cause faster wear.

The rotational speed should be properly adjusted. Since some plastics have reinforcing agents, such as glass fiber, minerals or other fillers. These substances often have much greater friction on metal materials than molten plastics.

If use high rotational speed, while increasing the shear force on the plastics, it is also easy to shred the reinforced fibers. The shredded fibers contain sharp ends so that the abrasive force is greatly increased. Inorganic minerals are gliding at a high speed on the metal surface, and the scraping effect is not slight. All in all, the speed should not be adjusted too high.

The screw rotates in the barrel, and the friction between the material and the two makes the screw and the working surface of the barrel gradually wear out, then the screw diameter is gradually getting shorter and the barrel’s inner diameter increases. In this way, the gap between the screw and the barrel gets bigger and bigger because of the abrasion.

However, due to the barrel in front of the head and the resistance of the manifold has not changed, so it increases the leakage flow of extruded material, that is, the material’s feeding flow increases from the gap to the feeding direction. As a result, the machine’s production capacity decreased. This phenomenon in turn increases the residence time of material in the barrel, resulting in material decomposition. If it is PVC, the hydrogen chloride gas produced while decomposing will strengthen the corrosion of the screw and barrel.

Because the material is not plasticized uniformly, or metal impurities are mixed into the material, the screw rotation torque force will increase suddenly. This torque exceeds the strength limit of the screw, and leads to the screw being twisted off. This is unconventional accident damage.

These are some common causes of screw wear, hope that the above content can offer you a better understanding and knowledge of the extrusion screw.

Reducing the abrasion of the screw and extending the working life of the screw will greatly lower the maintenance costs of the equipment, ensure the quality of the product and bring higher economic benefits to your company.