Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

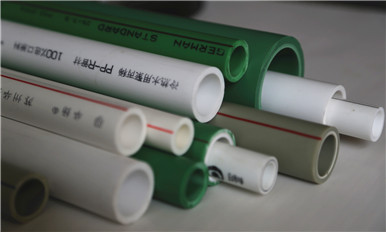

In the world of plumbing and water supply systems, Polypropylene Random Copolymer (PPR) pipes have emerged as a reliable and versatile solution. Known for their durability, ease of installation, and wide range of applications, PPR pipes have become a preferred choice for many professionals. This article explores the characteristics, benefits, and various uses of PPR pipes in both residential and industrial contexts.

What is PPR?

PPR, or Polypropylene Random Copolymer, is a type of plastic material produced by the polymerization of propylene monomers with random incorporation of ethylene monomers. This random incorporation enhances the material's properties, making it suitable for a variety of applications. PPR pipes are manufactured using this material and are known for their excellent chemical resistance, thermal stability, and mechanical strength.

Characteristics of PPR Pipes

PPR pipes possess several key characteristics that make them ideal for plumbing and water supply systems:

Durability: PPR pipes are highly durable and can withstand high pressure and temperature fluctuations. This makes them suitable for both hot and cold water applications.

Chemical Resistance: PPR pipes are resistant to a wide range of chemicals, making them suitable for transporting various fluids without degradation.

Non-Toxic: PPR pipes are non-toxic and safe for drinking water applications. They do not leach harmful substances into the water supply.

Smooth Interior Surface: The smooth interior surface of PPR pipes reduces friction, ensuring efficient water flow and minimizing pressure loss.

Thermal Insulation: PPR pipes have good thermal insulation properties, which help maintain the temperature of the fluid being transported.

Longevity: With a lifespan of up to 50 years or more under proper conditions, PPR pipes offer long-term reliability.

Ease of Installation

One of the significant advantages of PPR pipes is their ease of installation. They can be joined using a simple heat fusion process, which involves heating the pipe and fitting ends and then joining them together. This creates a seamless and leak-proof connection, eliminating the need for additional sealing materials.

Cost-Effectiveness

PPR pipes are cost-effective both in terms of material costs and installation expenses. Their lightweight nature reduces transportation costs, and the quick and straightforward installation process saves labor costs. Additionally, the longevity and low maintenance requirements of PPR pipes contribute to their overall cost-effectiveness.

Environmental Friendliness

PPR pipes are environmentally friendly due to their recyclability and low environmental impact during production. Unlike some other piping materials, PPR does not release harmful chemicals into the environment. This makes them a sustainable choice for modern plumbing systems.

Residential Plumbing

PPR pipes are extensively used in residential plumbing systems for both hot and cold water supply. Their ability to withstand high temperatures and pressures makes them ideal for distributing hot water from boilers to taps and showers. Additionally, their non-toxic nature ensures safe drinking water supply throughout the household.

Industrial Applications

In industrial settings, PPR pipes are used for a variety of purposes, including:

Chemical Transport: Due to their excellent chemical resistance, PPR pipes are suitable for transporting a wide range of chemicals and industrial fluids without the risk of corrosion or degradation.

Compressed Air Systems: PPR pipes are used in compressed air systems due to their ability to handle high pressure and maintain air purity.

Food and Beverage Industry: PPR pipes are safe for use in the food and beverage industry, where they transport water and other fluids in processing and production lines.

Heating Systems

PPR pipes are commonly used in underfloor heating systems and central heating systems. Their thermal insulation properties help maintain the temperature of the heated water, ensuring efficient heat distribution throughout the building.

Agriculture and Irrigation

In agriculture, PPR pipes are used for irrigation systems due to their durability and resistance to chemicals commonly used in farming. They are also used in greenhouse heating systems and for transporting water to livestock.

PPR vs. PVC

While both PPR and PVC are popular piping materials, they have distinct differences:

Temperature Resistance: PPR pipes can handle higher temperatures compared to PVC pipes, making them more suitable for hot water applications.

Chemical Resistance: PPR pipes have better chemical resistance, especially against acidic and alkaline substances.

Installation: PPR pipes are typically joined using heat fusion, whereas PVC pipes are joined using solvent cement, which can be more labor-intensive.

PPR vs. Copper

Copper pipes have been traditionally used in plumbing, but PPR pipes offer several advantages:

Cost: PPR pipes are generally more cost-effective than copper pipes.

Corrosion Resistance: Unlike copper, PPR pipes do not corrode, ensuring a longer lifespan in certain environments.

Ease of Installation: PPR pipes are easier to install due to their lightweight and heat fusion joining process.

Despite their numerous advantages, PPR pipes have some challenges and considerations:

UV Sensitivity: PPR pipes are sensitive to UV light and should be protected from direct sunlight to prevent degradation.

Thermal Expansion: PPR pipes have a higher coefficient of thermal expansion compared to metals, which should be considered during installation to prevent stress and potential damage.

Initial Cost: While cost-effective in the long run, the initial cost of PPR pipes and fittings can be higher than some other materials.

PPR pipes have revolutionized the plumbing and water supply industry with their exceptional durability, chemical resistance, and ease of installation. Their versatility and wide range of applications, from residential plumbing to industrial uses, make them a preferred choice for many professionals. As technology advances and the demand for sustainable and efficient piping solutions grows, PPR pipes are likely to remain at the forefront of modern plumbing systems.

Golden Far East provides high-quality production lines to produce PPR pipes in various sizes and capacities. If you need more information about the production line, please contact us to get a quotation.