Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

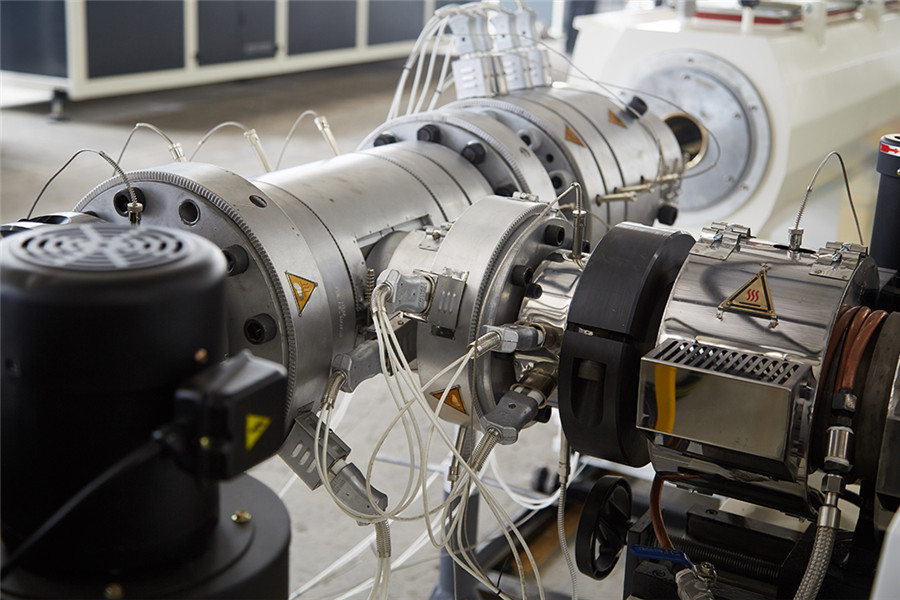

Main extruders are two extruders, one is for making middle layer PVC, another one is for making outer and inner layer PVC. different model extruders to satisfy customer's request.

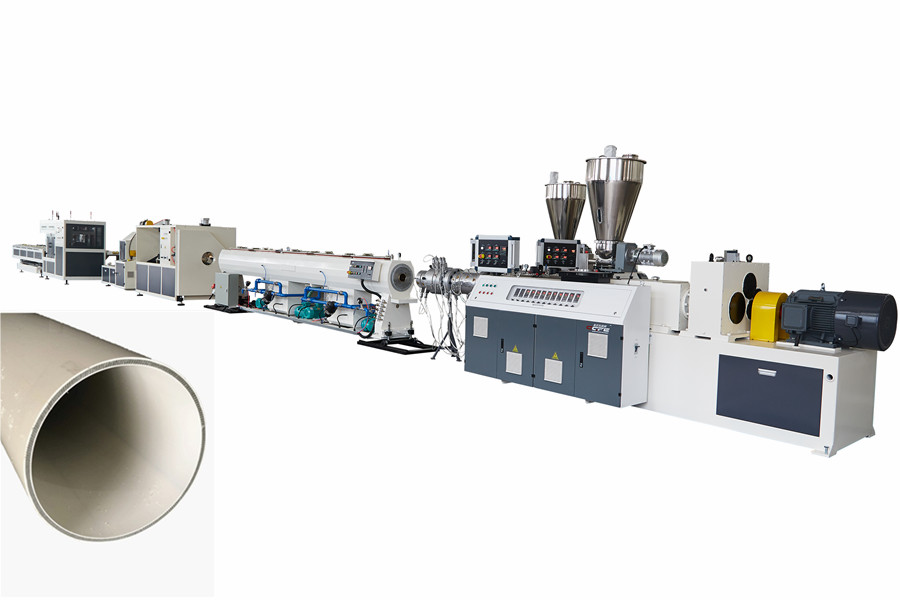

This production line is mainly used in producing of PVC pipes with various tube diameter and wall thickness in the aspects such as the agricultural, constructional, and cable laying etc. the unit is composed of the conical twin-screw extruder, vacuum modes such as two claw, three claw and so on. Choose the saw blade cutting type or the planetary cutting type. It is additionally attached manufacturer of the inner wall spiral coil according to the client requirements. Produce inner wall spiral pipe, inner wall hollow and core foam pipe, ect. The planetary cutting machine is fully automatic computer control, it has such advantages of simple operation, reliable property, ect. It has reached world advanced level.

| Pipe diameter(mm) | 50,75,90,110,160 | 75,90,110,160,200,250 |

| Extruder(for middle layer) | 65/132 | 80/156 |

| Extruder (for outer& inner layer) | 65/132 or 55/120 | 65/132 |

| Length of vacuum tank(mm) | 6000 | 6000 |

| Haul-offs machine | 3claw | 3claw |

| Cutting machine | planetary cutting | planetary cutting |

Performance advantages: more than 2sets SJZ series conical twin screw extruder machines are used to co extrude three-layer PVC pipes. The pipe sandwich layer is made of high calcium PVC or PVC foaming material.

1. The main machine adopts super wear-resistant alloy screw barrel, the twin-screw feeder is evenly fed, and the powder is not bridged;

2. The optimized design of PVC three-layer mold, the runner is chrome plated and highly polished, wear-resistant and corrosion-resistant; with the special sizing sleeve, the production speed is fast and the pipe quality is good;

3. The cutter adopts rotary clamping device, which adapts to different pipe diameters and avoids the trouble of frequent replacement of clamps. Equipped with a new adjustable floating chamfering mechanism, which can be adjusted according to pipe diameter and wall

Adjust the chamfering size, cut and chamfering in one step. Closed vacuum device, better chip suction effect.

PVC composite pipe is a new type of composite drainage pipe. The pipe is a three-layer coextrusion composite drain pipe, the inner and outer walls of which are hard PVC, to ensure the enough strength and other physical properties of the pipe. The middle layer is made of special formula PVC, the relative density is 0.7-0.9g/cm3, and the structure of the layer is micro closed pore. This kind of special structure cleverly uses the principle of type I structure in mechanics of materials. It can be observed that the intermediate interlayer is soft colloid, which not only has all the advantages of PVC (empty wall) pipe, but also has the advantages of sound insulation, heat insulation, shock resistance, impact resistance, light weight and low price over the solid wall pipe.

1. Light weight (density 0.9-1.2g/cm3), low price.

2. The inner wall is smooth, the friction coefficient is small, and the fluid transportation efficiency is improved

3. It has high impact strength, and its ring steel is twice of ordinary PVC-U

4. It has good weather resistance, can be used at - 30 ℃ - 70 ℃, and has good dimensional stability when the temperature changes

5. Special composite multi-layer structure greatly improves the sound insulation performance of pipes

6. Strong self ignition and self extinguishing performance

7. Excellent corrosion resistance

8. The service life of the pipeline is increased, which is 4-7 times of that of the ordinary pipeline

9. The installation cost of the composite drain pipe is lower than that of the general pipe, and the performance of the composite drain pipe is higher than that of the general polyethylene pipe due to the comprehensive comparison of its corrosion resistance, wear resistance, weather resistance and many other factors.

wooden pallet, PE film package.