Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

In the ever-evolving landscape of industrial manufacturing, the quest for efficiency and productivity is an ongoing endeavor. Nowhere is this pursuit more critical than in industries reliant on PVC pipe production, where the demand for high-quality products, cost-effective solutions, and timely delivery is incessant. Central to meeting these challenges head-on are PVC pipe extrusion machine lines – sophisticated systems designed to automate and streamline the production process. In this comprehensive exploration, we delve into the strategies and techniques for optimizing production with PVC pipe extrusion machine lines, uncovering key considerations, benefits, and best practices that drive success in this dynamic field.

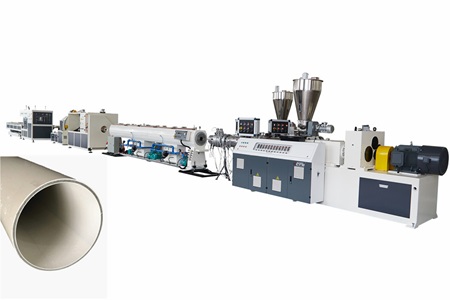

At the heart of PVC pipe production lies the PVC pipe extrusion machine line – a multifaceted system meticulously engineered to transform raw materials into finished products with precision and efficiency. Comprising a series of interconnected components, including extruders, die heads, vacuum tanks, haul-off units, cutters, and auxiliary equipment, these machine lines orchestrate a symphony of processes to yield uniform, high-quality PVC pipes. The extruder serves as the workhorse, melting the PVC resin and shaping it into the desired pipe profile through a precision-engineered die. Meanwhile, the vacuum tank and haul-off unit collaborate to regulate pipe dimensions and ensure consistency throughout the production run.

The adoption of PVC pipe extrusion machine lines heralds a multitude of benefits for manufacturers striving to optimize their production processes:

Enhanced Efficiency: By automating key manufacturing processes, PVC pipe extrusion machine lines eliminate the inefficiencies inherent in manual labor, resulting in accelerated production cycles and heightened overall efficiency. Manufacturers can produce a higher volume of pipes in less time, thus meeting escalating market demand with ease.

Consistent Quality: With meticulous control over critical parameters such as temperature, pressure, and speed, PVC pipe extrusion machine lines uphold unwavering standards of product quality. This consistency is paramount for meeting industry specifications and satisfying the discerning requirements of customers, thereby fostering trust and loyalty in the brand.

Cost-Efficiency: Despite the initial capital outlay required for installation, PVC pipe extrusion machine lines yield substantial long-term cost savings. Reduced labor costs, diminished scrap rates, and heightened production output collectively contribute to improved profitability over time, making them a prudent investment for forward-thinking manufacturers.

Versatility and Adaptability: PVC pipe extrusion machine lines exhibit remarkable versatility, capable of accommodating a diverse array of pipe sizes, shapes, and specifications. This inherent flexibility empowers manufacturers to swiftly respond to shifting market dynamics and customer preferences, thereby maintaining a competitive edge in a dynamic industry landscape.

To unlock the full potential of PVC pipe extrusion machine lines and optimize production outcomes, manufacturers can employ a range of strategic approaches:

Rigorous Maintenance Regimens: Proactive maintenance schedules are indispensable for preserving the operational integrity of extrusion equipment and mitigating the risk of unplanned downtime. Regular inspections, lubrication routines, and preemptive replacement of worn components are essential practices that safeguard against disruptions to production continuity.

Continuous Process Refinement: Fine-tuning extrusion parameters such as temperature profiles, screw speeds, and die geometries can yield substantial improvements in production efficiency and product quality. Through iterative experimentation and data-driven analysis, manufacturers can pinpoint the optimal settings that maximize throughput while minimizing material wastage.

Empowered Workforce: The proficiency and expertise of machine operators play a pivotal role in maximizing the efficacy of PVC pipe extrusion machine lines. Comprehensive training programs that impart technical knowledge, troubleshooting skills, and safety protocols equip operators with the competencies needed to navigate complex production challenges adeptly, thus enhancing overall operational efficiency.

Robust Quality Assurance Protocols: Implementing stringent quality control measures at every stage of the production process is imperative for upholding the integrity of the final product. Regular inspections, dimensional analyses, and adherence to industry standards fortify confidence in product quality, instilling trust in customers and fostering enduring relationships.

In an era characterized by relentless technological advancement and escalating market demands, PVC pipe extrusion machine lines emerge as indispensable assets for manufacturers seeking to optimize their production capabilities. With their capacity to enhance efficiency, ensure quality consistency, drive cost-efficiency, and accommodate evolving market dynamics, these advanced systems represent a cornerstone of success in the PVC pipe manufacturing landscape. By embracing strategic optimization strategies, including rigorous maintenance protocols, continuous process refinement, investment in human capital, and unwavering commitment to quality assurance, manufacturers can harness the full potential of PVC pipe extrusion machine lines to realize sustained growth, profitability, and competitiveness in the global marketplace. As the industry continues to evolve, those equipped with the foresight to invest in cutting-edge technology and operational excellence will undoubtedly emerge as leaders in the field, driving innovation and shaping the future of PVC pipe production.