Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

In the intricate realm of manufacturing, the creation of PS (Polystyrene) decorative profiles demands a meticulous and multifaceted approach that seamlessly combines precision engineering with artistic flair. This comprehensive guide aims to provide manufacturers with an in-depth exploration of PS decorative profile production lines, delving into the key components, advanced technologies, and best practices that contribute to the development of aesthetically pleasing, high-quality decorative profiles.

At the core of architectural elegance, PS decorative profiles serve as vital elements in interior design, providing architects, designers, and homeowners with versatile solutions for adding sophistication and character to spaces. The production process of these profiles not only adheres to rigorous quality standards but also allows for the creative expression of design flexibility.

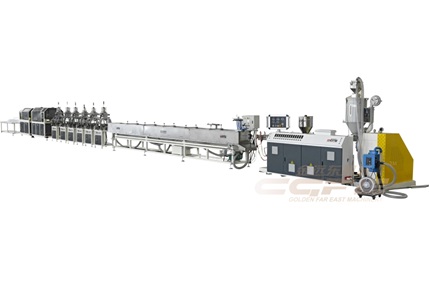

A robust and successful PS decorative profile production line relies on the integration of precision machinery and streamlined processes. From state-of-the-art extruders and molds to cutting-edge cutting and finishing equipment, each component plays a pivotal role in shaping the final product. Employing high-quality raw materials, such as specialized polystyrene blends, ensures the durability and longevity of the finished decorative profiles.

Extrusion serves as the linchpin of PS decorative profile production, enabling manufacturers to fashion profiles with intricate designs and consistent dimensions. Advanced extrusion techniques, including co-extrusion and multi-material extrusion, empower the incorporation of various colors and textures into the profiles, providing an extensive canvas for design customization that meets the demands of even the most discerning designers.

Precision Molding for Intricate Details

Molding processes play a pivotal role in enhancing the detailed aesthetics of PS decorative profiles. Precision molding techniques, such as injection molding, allow for the creation of intricate patterns, textures, and ornate details. This ensures that the final decorative profiles not only meet but exceed the expectations of designers and customers, delivering on the promise of visual opulence.

Finishing Touches: Surface Treatments and Coatings

The culmination of the creative process in PS decorative profile production lies in the finishing touches. Various surface treatments, such as painting, foiling, or laminating, elevate the appearance of the profiles, providing additional protection against wear and tear. Incorporating UV-resistant coatings ensures the longevity of the profiles, guaranteeing that they maintain their aesthetic allure over time, even in challenging environments.

Quality Control: Ensuring Excellence in Every Profile

The commitment to maintaining stringent quality control processes is paramount in PS decorative profile production. Rigorous inspections at every stage of the production line, coupled with the integration of advanced quality control technologies like automated optical inspection (AOI), guarantee that each profile meets and often surpasses the specified standards. This meticulous attention to quality ensures that the decorative profiles are not just manufactured; they are crafted to embody excellence.

Embracing Sustainability in PS Decorative Profile Production

In an era dominated by environmental consciousness, sustainable manufacturing practices take center stage. Manufacturers of PS decorative profiles are increasingly embracing recycled materials, optimizing energy usage, and implementing waste reduction strategies. This commitment not only aligns with eco-friendly initiatives but also enhances the overall corporate responsibility of the manufacturing process, contributing to a more sustainable and responsible industry.

As manufacturers navigate the intricate landscape of PS decorative profile production lines, they embark on a delicate journey where precision engineering intertwines with artistic creativity. This comprehensive guide has sought to provide a thorough understanding of the essential components, innovative techniques, and quality control measures that contribute to the creation of decorative profiles that transcend mere functionality. By embracing the principles outlined here, manufacturers are not just crafting profiles; they are shaping timeless pieces of elegance that leave an indelible mark on diverse spaces. As the industry continues to evolve, the fusion of technology, creativity, and sustainability will undoubtedly shape the future of PS decorative profile production, ushering in an era where profiles are not just manufactured but are truly elevated to the status of timeless works of art.